Fiber laser metal cutting machine manufacturer introduces you: The main components of laser cutting machine are circuit system, transmission system, cooling system, light source system, dust removal system. The main parts that need to be maintained in daily life are mainly the cooling system (to ensure the constant temperature effect), the dust removal system (to ensure the dust removal effect), the optical path system (to ensure the beam quality), and the transmission system (the focus needs to be paid to ensure normal operation). In addition, a good working environment and correct operating habits are also conducive to extending the life of the equipment.

I. Maintenance of cooling system

The water inside the water cooler needs to be replaced regularly, and the replacement frequency is usually one week. The water quality and temperature of the circulating water directly affect the life of the laser tube. It is recommended to use pure or distilled water and control the water temperature below 35 ° C. If you do not change the water for a long time, it is easy to form scale, which will block the waterway, so you must change the water regularly.

Second, keep the water flowing at all times. The cooling water is responsible for taking away the heat generated by the laser tube. The higher the water temperature, the lower the light output power (preferably 15-20 ° C water temperature); when the water is cut off, the tube end will burst due to the heat accumulation in the laser cavity, and even the laser power supply will be damaged . Therefore, it is necessary to check whether the cooling water is unblocked at any time. When the water pipe is bent (deadly bent) or falls off, so that the pump fails, it must be repaired in time to prevent the power from dropping or even causing damage to the equipment.

Maintenance of dust removal system

After being used for a long time, the fan will accumulate a lot of dust, which will affect the exhaust and deodorization effects and generate noise. When it is found that the suction power of the fan is insufficient and the smoke is not smooth, first turn off the power, remove the inlet and outlet pipes from the fan, remove the dust inside, and then turn the fan upside down and flip the blades inside until it is clean Then install the fan. Fan maintenance cycle: about one month.

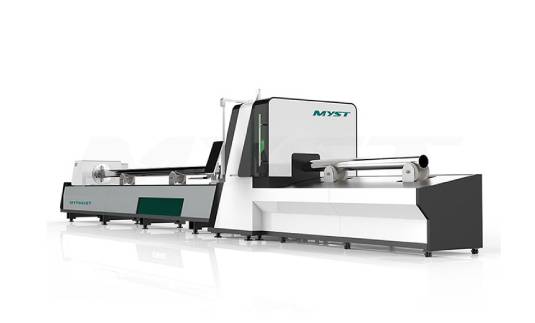

Tube Laser Cutting Machine

After the

tube laser cutting machine works for a period of time, the surface of the lens will be coated with a layer of ash due to the working environment, which will reduce the reflectivity of the reflective lens and the transmittance of the lens, and ultimately affect the working power of the laser. At this time, use an absorbent cotton dipped in ethanol to carefully wipe the rotation along the center of the lens to the edge. The lens should be wiped gently to avoid damaging the surface coating; the process of wiping should be handled gently to prevent falling; please keep the concave surface down when installing the focusing lens. In addition, usually reduce the number of ultra-high-speed perforations as much as possible, and the use of conventional perforations can extend the life of the focusing lens.

Fourth, transmission system maintenance

Smoke will be generated during the long-term cutting of the equipment. Fine dust will enter the equipment through the dust cover, which will adhere to the rail rack. Long-term accumulation will increase the wear of the rail rack. Rack guide rails are relatively precise accessories. A large amount of dust is deposited on the surfaces of guide rails and linear shafts for a long period of time, which greatly affects the processing accuracy of the equipment, and will form pits on the surface of the linear shafts of the guide rails, which shortens the equipment life. Therefore, in order for the equipment to work normally and stably, and to ensure the processing quality of the product, it is necessary to carefully do the daily maintenance of the guide rails and linear shafts, and regularly perform dust removal and cleaning. After cleaning the dust, grease the rack and lubricate it with lubricating oil. Each bearing should also be regularly oiled, so as to maintain flexible driving and accurate machining, and prolong the service life of the machine tool.

The environment of the workshop should be kept dry and well ventilated. The ambient temperature is between 4 ° C and 33 ° C. In summer, precautions should be taken to prevent condensation of the equipment, and in winter, the laser equipment must be protected against freezing.

The

fiber laser metal cutting machine should be far away from the electrical equipment sensitive to electromagnetic interference to prevent the equipment from receiving electromagnetic interference for a long time. Keep away from sudden high-power interference caused by large power and strong vibration equipment. High-power interference sometimes causes machine failure. Although rare, it should be avoided as much as possible. Therefore, such as large electric welding machines, giant electric mixers and large power transmission and transformation equipment, etc., should be kept away. Strong vibration equipment is self-evident, such as forging presses, vibrations caused by close-range motor vehicles walking, etc., the obvious vibration of the ground is not good for accurate carving.

During the work of the equipment, the operator must observe the working condition of the equipment at any time. If there is an abnormal situation, immediately cut off all power, promptly troubleshoot or report to the supervisor, and actively take corresponding measures. Regularly statistics the use of the machine, and keep a regular record of each part of the laser cutting machine. If the results are not good, replace them in time to prevent problems before they occur.

Do not process a material before clarifying whether it can be irradiated or heated with a laser, to avoid the potential danger of generating smoke and vapors and damaging the laser equipment.

If you use the above maintenance skills, I believe that your equipment will last longer and work more efficiently!