Generally speaking, laser marking machine can be divided into large size and small size according to specifications. Many people are not familiar with some large laser marking machines, but for many portable UV lasers marking machines, I still know very well, because these products usually appear in our field of vision. As long as you pay attention to life, you can master these aspects, so what is the small laser marking machine around us? What purpose?

Where will the small laser marking machine be used?

One, small advertising design

For many people, this may be easy to understand, because when designing such small advertisements, small laser marking machines are actually important basic tools. For example, many of the banners we saw around were actually made using this small laser marking machine, including some small individual advertisements. In fact, these small laser marks are actually used. Therefore, this small laser marking machine is actually a very important basic tool for small advertising design. In addition, the equipment has high working efficiency and good cost control. Well, this will naturally be a very practical product.

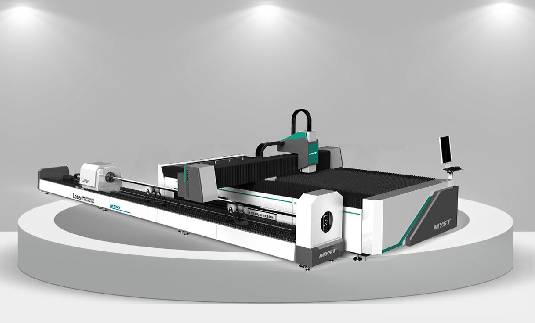

Portable Fiber Laser Marking Machine For Metal

Second, outdoor marking production

Many people may think that this laser marking machine is only visible at the laser marking machine manufacturer.

In fact, this is also a wrong concept. In fact, this situation is often encountered when producing many outdoor advertisements.

So this situation is actually very easy to understand, especially when this small laser marking machine is used to produce some outdoor advertising spots that are not very large, this equipment will be more practical and convenient than traditional ones. Red production, its efficiency is dozens of times. And the small laser marking machine is also very convenient to carry.

Three, office use

Many large integrated offices involve many specific businesses, such as the advertising departments of many large enterprises.

In their offices, such small laser marking machines are almost everywhere because of the demand in the office. Or when it comes to product templates, it is actually necessary to use this very practical small laser marking machine. Therefore, the standing of this small laser marking machine actually has many practical meanings for many people. Some other public offices sometimes use this small laser marking machine, which can solve many problems for the office. Generally, such small laser marking machines are more common in daily life than large laser marking machines. The applications in these areas mentioned above are actually expanding. Even we can predict that this small laser marking machine will even appear in many people's homes in the near future.

Fiber laser marking machine supplier believes that it is a good choice for people's leisure and entertainment, so it is very likely that the expansion development of small laser marking machine is still full of market potential, everyone can be on the market Budding.