Traditional metal thermal processing has flame, plasma and other cutting methods. As a modern cutting tool capable of perfecting fine cutting-metal laser cutting machine. two laser technologies of fiber metal laser cutting machine and CO2 metal laser cutting machine began to fight fiercely. Many metal processing companies do not understand the difference between the two methods. Professional laser cutting machine supplier to share with you.

In fact, the same as the high-power metal laser cutting machine, the fiber metal laser cutting machine has a faster cutting speed and higher quality than the CO2 metal laser cutting machine, and the maintenance cost and operation cost are greatly reduced. Although the more powerful CO2 laser cutting machine can cut thicker plates, it can't stop the audience's favor for fiber metal laser cutting machine.

First of all, the two laser beams are transmitted in different ways. Fiber lasers are not transmitted through mirrors like CO2 (the medium that generates laser beams), which makes fiber laser technology without scope limitations between the mirrors. Similarly, when compared with gas cutting systems of the same power, the system is more compact due to the ability to bend the fiber.

The electro-optical conversion efficiency of the fiber metal laser cutting machine is far beyond that of the CO2 metal laser cutting machine. Users can use the fiber metal laser cutting machine to achieve higher power efficiency, which is between 25% and 30%. It is a carbon dioxide cutting system of the laser cutting machine brand. The actual utilization rate is three to five times. Compared with carbon dioxide cutting system, the energy efficiency of fiber-optic metal laser cutting machine is increased by more than 90%.

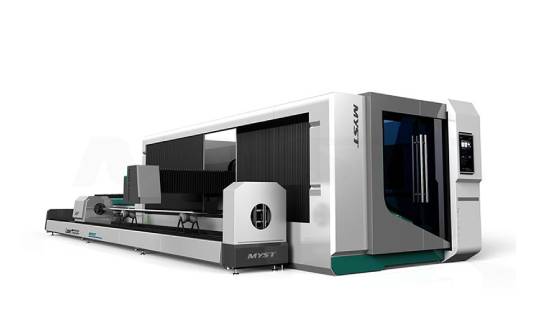

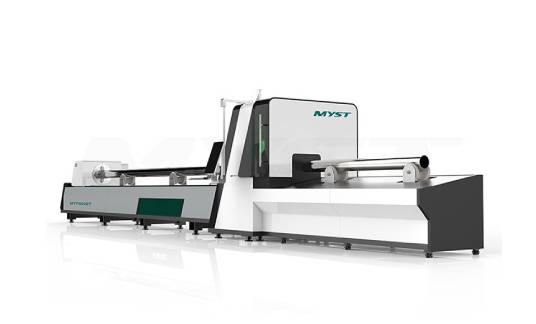

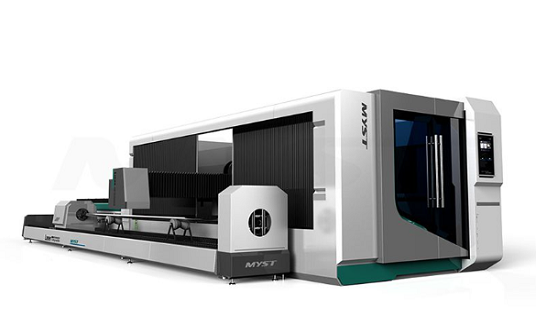

Fiber Laser Metal Cutting Machine

In terms of maintenance, cheap CNC metal laser cutter needs regular maintenance, such as the calibration of the mirror, the maintenance of the resonator, etc. The fiber metal laser cutting machine is maintenance-free.

Due to the short wavelength characteristics of fiber metal laser cutting machines, some non-conductive metal materials, as well as brass and copper, are more likely to absorb fiber laser beams. Because the fiber laser beam is more concentrated and the light spot is smaller, the fiber metal laser cutting machine cuts faster when cutting thin and medium plates. When cutting materials up to 6mm thick, the cutting speed of the 1.5kW fiber laser cutting system is equivalent to the cutting speed of the 3kW CO2 laser cutting system.

The CO2 gas laser system needs regular maintenance; the turbine needs maintenance and refurbishment; the reflector needs maintenance and calibration; and the resonant cavity needs to be cleaned regularly to ensure the purity of carbon dioxide, which is expensive. For a high-power (above 1000w) carbon dioxide metal laser cutting machine of a laser cutting machine brand, these together need to invest at least 20,000 US dollars per year. On the other hand, fiber laser cutting solutions produced by laser cutting machine brand manufacturers require little maintenance.

Fiber laser metal cutting machine maintenance and maintenance should be carried out from the following aspects:

1. Check the steel belt frequently to ensure that it is tight. Otherwise, if something goes wrong during operation, it may hurt people and cause death. The steel belt looks like a small thing, but the problem is still a bit serious.

2. Check the straightness of the track and the verticality of the machine every six months, and find that it is abnormal and timely maintenance and debugging. Without this, the effect of cutting may not be very good, the error will increase and affect the cutting quality. This is the top priority and must be done.

3. Use a vacuum cleaner to remove the dust and dirt in the machine once a week. All electrical cabinets should be tightly closed to prevent dust.

4. The guide rails should be cleaned regularly to remove dust and other debris, to ensure that the equipment racks are cleaned frequently, and lubricating oil is added to ensure lubrication without debris. The guide rail should be cleaned and lubricated frequently, and the motor should also be cleaned and lubricated frequently. The machine can move better during cutting, cut more accurately, and the quality of the cut product will improve. .

5. The dual focal length laser cutting head is a fragile item on the laser cutting machine. Long-term use will cause damage to the laser cutting head. Regular inspections and maintenance are required. If any deformation or other forms appear, you should know that the laser cutting head has been damaged a little at this time, and you need to replace it. Failure to replace will affect the cutting quality and increase costs, and some products may need to be reprocessed to reduce production efficiency. The laser cutting head should be produced by a professional manufacturer, and it should be carefully checked when purchasing, so as to avoid problems when it is used.