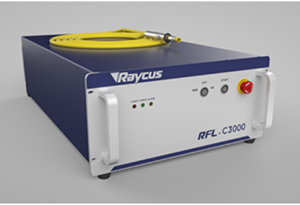

In the working process of the fiber laser metal cutting machine, as the cutting time increases, the machine parts will generate heat. Failure to cool down in time will cause the laser power to gradually attenuate or even be damaged. In order to ensure the normal operation of the machine, reduce the number of machine parts. Replacement cost, the DIY fiber laser cutter is equipped with a water chiller for temperature control. As a circulating water device, the water chiller is responsible for cooling the laser generator and cutting the head. It is an important part of the metal fiber laser cutting machine. With the timely cooling of the water chiller, the normal operation of the desktop fiber laser cutting machine can be effectively stabilized, and the efficiency and the cutting speed of the thin plate can be improved under high-intensity work, ensuring the high-precision operation of the equipment, reducing the edge of the slit, and extending the laser generation The service life of the cutter, cutting head and fiber optic laser cutting machine saves the maintenance cost of the equipment and the replacement cost of accessories.

Commonly used brands of CNC fiber laser cutters are S&A and Tongfei. The desktop fiber laser cutters produced by our factory generally use S&A chillers, but customers can also choose Tongfei’s chillers, the model of the chiller, and the generator The power is consistent.

Water chiller model:

• S&A: 500W 750W 1000W 1500W 2000W 3000W 4000W 6000W 8000W 12000W

• Tong fei: 1000W 1500W 2000W 3000W 4000W 6000W 8000W 10000W 12000W

In order to ensure the stable operation of the CNC laser steel cutting machine, we also need to maintain the chiller regularly.

1. Regularly clean the heat sink. The cleaning method is: carefully brush the heat sink with a brush, and then blow it clean with compressed air. If necessary, clean and rinse with water and a special air-conditioning fin cleaning agent (common name dust).

2. Clean the condenser regularly (the method is the same as above).

3. Regularly check the water level in the water tank of the chiller. If the water level is too low, add pure water or deionized water in time.

4. Regularly check the electrical wiring terminals and remove dust (to be done after power off).

5. Regularly check whether the joints in the water system are leaking, whether the pipeline is aging, and if there is water leakage, replace the relevant components in time.

6. The water inside the chiller needs to be replaced regularly, and the general replacement frequency is one month. The water quality of the chiller is used for a long time and it is easy to form scale, which will block the waterway and cause the water flow to drop and reduce the cooling effect. Therefore, regular water replacement is treated as the primary problem. Regularly check the water quality in the water tank of the chiller. If the quality of the cooling water becomes poor, turbid, and its transparency decreases, all the deteriorated cooling water must be discharged in time and replaced with new cooling water. Try to choose distilled water, if there is no

Pieces can choose deionized water. Various manufacturers have requirements for water quality, so remember to meet the requirements, otherwise, long-term use of water that does not meet the standard will cause fouling inside the laser.

7. Regularly clean the impurities on the filter element of the chiller filter of the DIY fiber laser cutting machine. If the filter element is damaged, it should be replaced in time. The replaced filter element must use the standard filter element required by the manufacturer.