In today’s industrial manufacturing field, CNC fiber laser cutting machines have a wide range of applications in all walks of life due to their efficient and flexible processing advantages. Especially in metal processing, fiber laser metal cutting machine has almost become a must-have tool for all processing manufacturers, and People's daily life is closely related, but most people don't know how it works. Today, Mister Laser will take you to understand the working principle of laser fibra cutting machine, so that everyone can understand it more deeply.

The principle of laser cutting

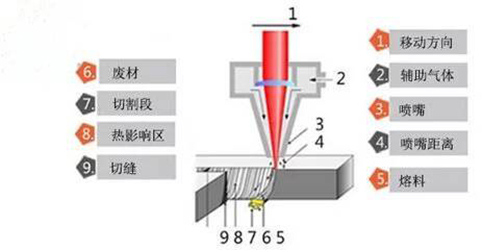

Laser cutting machine steel is to focus the laser light emitted from the laser into a high power density laser beam through the optical path system. The laser beam irradiates the surface of the workpiece to make the workpiece reach the melting point or boiling point, and the high-pressure gas coaxial with the beam blows away the molten or vaporized metal. As the relative position of the beam and the workpiece moves, the material will eventually form a slit, so as to achieve the purpose of cutting.

Advantages of fiber laser cutting

The laser cutting process uses an invisible beam to replace the traditional mechanical knife. Its working principle also determines that it has advantages that other processing methods do not have:

(1) High precision, fast speed, narrow cutting seam, minimum heat-affected zone, the smooth cutting surface without burrs.

(2) The laser cutting head does not touch the surface of the material and does not scratch the surface of the workpiece.

(3) The slit is narrow, the local deformation of the workpiece is extremely small, and there is no mechanical deformation.

(4) It can cut steel, steel, carbon steel, stainless steel, aluminum alloy plate, and other hard materials without deformation.

(5) Numerical control programming can process any plan, can cut the whole board with a large format, no need to open the mold, economical, and time-saving.

Laser cutting application industry

The advantages of fiber laser cutting also make laser metal cutting machine in the advertising industry, handicrafts, shoes, toys, computer embroidery cutting industries, clothing models, construction industries, metal cutting, electrical switch manufacturing, elevator manufacturing, household appliances manufacturing, kitchenware manufacturing, processing tools, And other machinery manufacturing and processing industries have a wide range of applications.

As a leader in laser smart equipment, MYST Laser-focused on providing great technical support and we have one professional laser cutting machine and laser marking machine communication Center. we will build our industry 4.0 and future plants, helping companies to build smart manufacturing and enabling smart manufacturing. Our company's values are customer-centric, strive-oriented, continuous innovation, and realize company value and employee dreams.