JINAN MYST Laser Equipment Co., Ltd. was founded in 2004, dedicated to the research and development, manufacturing, sales and maintenance of various high-end industrial laser equipment. It is a high-tech enterprise integrating R&D, production and sales of laser equipment; committed to providing laser equipment solutions for global users. The main products of enterprise include: fiber laser metal cutting machine, laser marking machine, laser cleaning machine, laser Welding machine, plasma cutting machine.

MYST Laser uses Lvdi Xinduhui as its company headquarters. It has successively built factories in Pingyin, Jinan, covering an area of 32,000 square meters. It provides a good foundation for the layout of the laser equipment industry chain, and ultimately providing stable and effective services for intelligent equipment. After 16 years of development, the company has gradually become a leading enterprise in the cutting machine market in northern China.

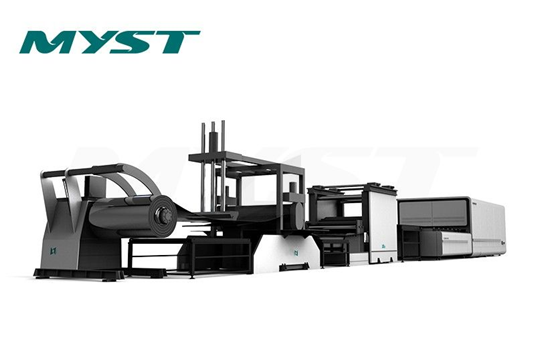

fiber laser metal cutter factory

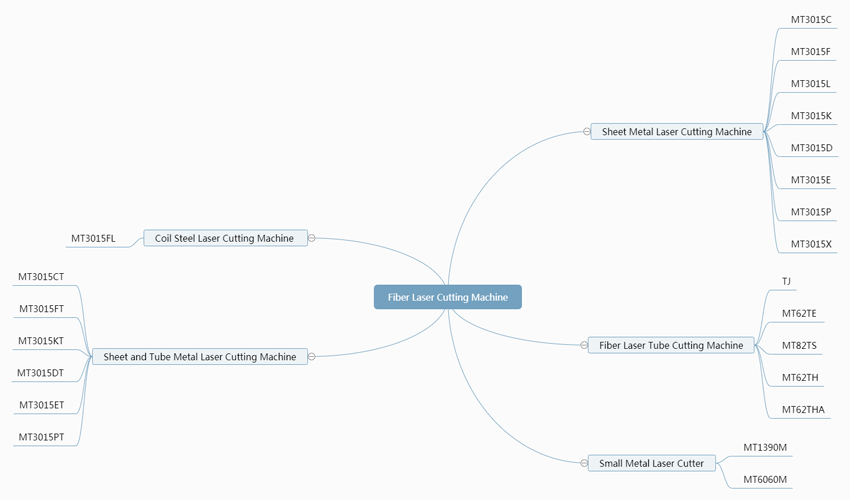

Today, MYST Laser introduces the company from two aspects: product classification and product naming.

The company's main product categories:

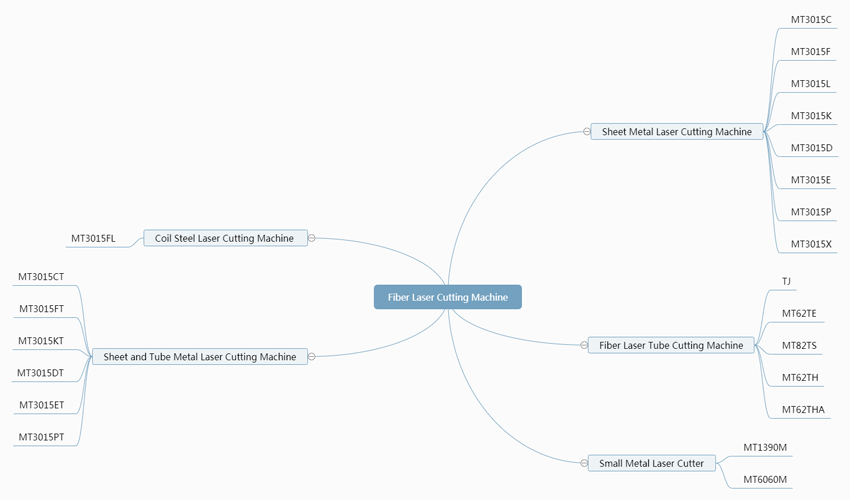

Classification of fiber laser cutting machines

The main products of MYST Laser include five categories: fiber laser cutting machine, laser welding machine, laser cleaning machine, laser marking machine and plasma cutting machine.

Fiber Laser Cutting Machine includes: Sheet Metal Laser Cutting Machine,Sheet and Tube Metal Laser Cutting Machine,Fiber Laser Tube Cutting Machine,Small Metal Laser Cutter and Coil Steel Laser Cutting Machine.

1 Sheet Metal Laser Cutting Machine includes: MT3015C laser metal cutting machine, MT3015F fiber laser cut machine, MT3015L laser sheet metal cutter, MT3015K Exchange table laser steel cutting machine, MT3015D Cover + Exchange table laser cutting machine for metal sheet, MT3015E Exchange table cnc fiber laser cutting machine, MT3015P Hight Power +Cover +Exchange table fiber optic laser cutter, MT3015X Exchange table fiber laser metal cutting machine, MTF3015 fiber laser metal cutting machine, MTF3015J(old model named) exchange table china fiber laser cutting machine, MTF3015G(old model named) full cover fiber laser metal cutting machine with exchange table.

Sheet Metal Laser Cutting Machine

2. Sheet and Tube Metal Laser Cutting Machine includes: MT3015CT Metal Plate + Rotary cnc metal laser cutter, MT3015FT Metal Plate + Rotary fiber laser metal cutting machine, MT3015KT Exchange table + Rotary fiber laser cutting machine, MT3015DT Cover + Exchange table + Rotary cheapest metal cutting laser machine, MT3015ET Exchange table + Rotary sheet and pipe laser cutting machine, MT3015PT Hight Power +Cover +Exchange table + Rotary fiber laser cutting machine, MTF3015R(old model named) cnc fiber laser cutting machine with rotary, MTF3015JR(old model named) cnc laser cutter steel With Rotary And Exchange Table, MTF3015GR(old model named) Fiber Laser Cutting Machine With Rotary Exchange Table and Cover.

Sheet and Tube Metal Laser Cutting Machine

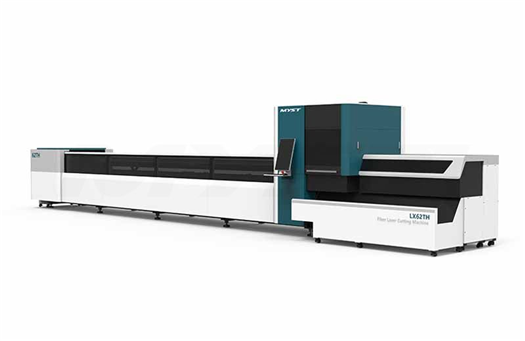

3. Fiber Laser Tube Cutting Machine includes: MT62TE metal tube laser cutting machine, MT82TS Standard metal tube laser cutting machine, MT62TH High Quality tube laser cutting machine, MT62THA Automatic Uploading + Downloading metal tube laser cutting machine, TJ Simple Metal fiber laser tube cutting machine, MTF6020T(old model named) laser tube cutting machine.

Fiber Laser Tube Cutting Machine

4. Small Metal Laser Cutter includes: MT1390M small fiber laser cutting machine, MTF0640 small fiber laser cutter, MTF1390(old model named) small metal laser cutter

Small Metal Laser Cutter

5. Coil Steel Laser Cutting Machine includes: MT3015FL Coil metal laser cutter

Coil Steel Laser Cutting Machine

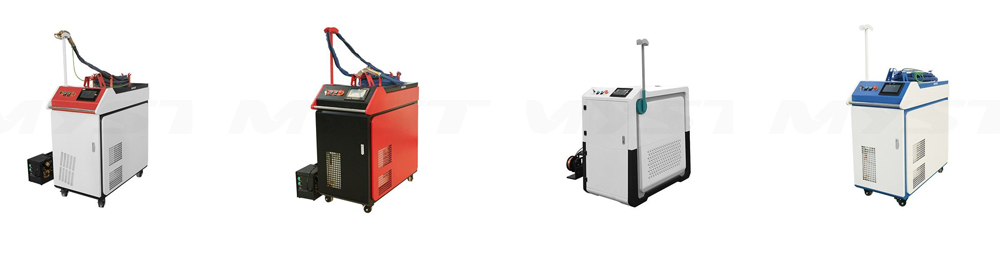

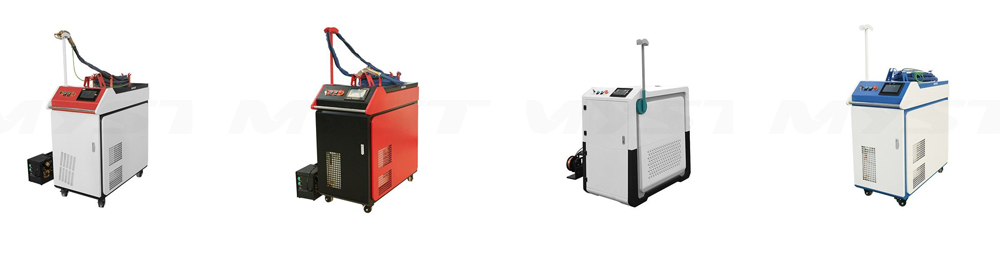

Laser Welding Machine includes: blue and white laser welding machine, red and white laser welding machine, black and red laser welding machine, patented laser welding machine(most popular style so far), high efficiency laser welding machine.

laser welding machine

Laser Cleaning Machine includes: green and white portable metal steel rust remover laser cleaning machine, trolley case handheld portable rust removal fiber laser cleaning machine, high efficiency laser cleaning machine

Laser cleaning machine

Laser Marking Machine includes: fiber laser marking machine,color laser marking machine,UV laser marking machine,3D laser marking machine,CO2 laser marking machine,online laser marking machine

laser marking machine

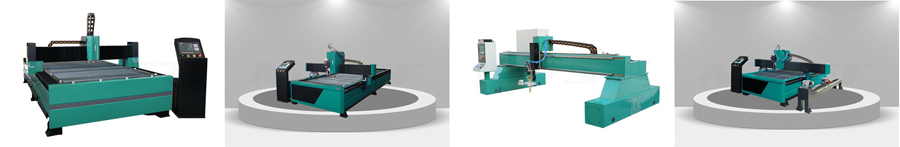

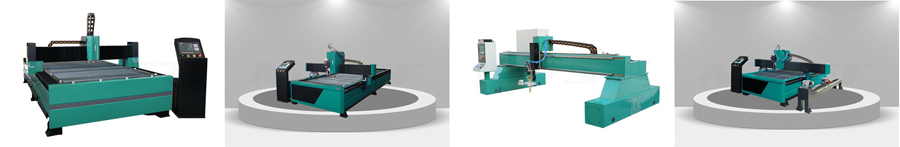

Plasma Cutting Machine includes: desktop plasma cutting machine,metal sheet and pipe plasma cutting machine,gantry type plasma cutting machine,multifunctional plasma cutting machine.

plasma cutting machine

Product naming:

1. Single table fiber laser cutting machine:

MT***C: economic tube welding bed, economic aviation aluminum beam, work area includes 0913/2513/3015/4015/6015/4020,applicable power 1000-2000W

MT****F: Standard pipe welding/standard plate welding machine bed, standard aviation aluminum beam, work area includes 3015/4015/6015/4020/6020/6025, applicable power 2000-6000W

MT****L: heavy-duty plate welded bed, heavy-duty aviation aluminum beam, work area includes 16030/20030, applicable power 2000-6000W

2. Exchange table fiber laser cutting machine:

MT****K: (open type, the bed is not too wide, suitable for exported customers,not need to split gantry)) economic tube welded bed, economic aviation aluminum beam, work area includes 3015/4015/6015, applicable power 1000-2000W

MT****D: (full cover, the bed is not too wide, suitable for exported customers,not need to split gantry) economic tube welded bed, economic aviation aluminum beam, work area includes 3015/4015/6015, applicable power 1000-2000W

MT****E1: (open type, the bed is not too wide, suitable for exported customers,not need to split gantry) standard pipe welding/plate welding bed, standard aviation aluminum beam, work area includes 3015/4015/6015/4020/6020/6025/8025, applicable power 3000- 12000W

MT****P1: (full cover, the bed is not too wide, suitable for exported customers,not need to split gantry) standard pipe welding/plate welding bed, standard aviation aluminum beam, work area includes 3015/4015/6015/4020/6020/6025/8025, applicable power 3000-12000W

MT****E: (open type, extra-wide beam, shipment needs to remove the beam, more suitable for china customers ,automatic loading and unloading is optional ) standard pipe welding/plate welding machine bed, standard aviation aluminum beam, work area includes 3015/4015/6015/4020/ 6020/6025/8025, applicable power 3000-12000W

MT****P: (full cover, super wide beam, shipment needs to remove the beam, more suitable for china customers ,automatic loading and unloading is optional) standard pipe welding/plate welding machine bed, standard aviation aluminum beam, work area includes 3015/4015/6015/4020/6020 /6025/8025, applicable power 3000-12000W

MT****X: heavy-duty plate welded bed, heavy-duty aviation aluminum beam, work area includes 4020/6025/8025/10025/12030, applicable power 6000-20000W

3. Professional tube cutting fiber laser cutting machine:

TJ: Only cut the metal round tube, applicable power 1000-3000W

MT****TE: economic tube welding machine bed, the work area includes Φ20-Φ160 Φ20-Φ220, and the applicable power is 1000-3000W

MT****TS: standard pipe welding bed, the work area includes Φ20-Φ120 Φ20-Φ160 Φ20-Φ220 Φ20-Φ350, applicable power 1000-3000W

MT****TH: heavy-duty pipe welding machine bed, the work area includes Φ20-Φ220 Φ20-Φ320, and the applicable power is 1000-4000W

MT****THⅢ: (three-chuck) heavy-duty pipe welding machine bed, the work area includes Φ20-Φ220 Φ20-Φ320, and the applicable power is 1000-4000W

4. Sheet and tube fiber laser cutting machine:

MT****CT/FT/KT/DT/ET/PT, economical tube welding (pipe cutting part) bed, the beam is the same as the above cutting board part, the work area includes Φ20-Φ160 Φ20-Φ220(Diameter 220mm is more cost effective), the applicable power is the same as the above cutting board part

5. Small fiber laser cutting machine:

MT****M Economical tube welding machine bed, modular motor, work area 1390/6060, applicable power 1000-1500W (1390 can reach 2000W)

6. High precision fiber laser cutting machine:

MT****G marble platform, linear motor, work area 6040/6060/9060, applicable power 1000-1500W

7. Automatic loading and unloading fiber laser cutting machine

MT**THA (cutting pipe automatic loading and unloading), it is expected to be divided into automatic loading and unloading and semi-automatic loading and unloading

MT****PA/XA is expected to be divided into three types: automatic unloading, automatic loading and unloading, automatic loading and unloading with stock library.

How can customers choose the right metal fiber laser cutting machine according to their work?

First of all, it is necessary to clarify the material used for processing, whether to cut a metal plate or a metal tube, in order to select the machine type.

Secondly, it is necessary to clearly define the length, width, thickness, and diameter of the material to be cut, so as to determine the processing breadth (the working breadth of the metal laser cut machine is determined by the size of the material being cut.) and model of the machine.

Finally, select the power of the machine according to the thickness range of the material to be cut. Just tell our company's sales staff the above information, and through the above information, our company's sales staff can recommend the laser cut steel machine that suits your work needs.

MYST Laser Equipment Co., Ltd. adheres to the business philosophy of "Quality First", practically starting from the customer's point of view, insisting on scientific and technological innovation as the forerunner, has developed a batch of internationally advanced laser processing equipment, and its products have always maintained a technologically leading advantage in the market.

Products are widely used in automobiles, motorcycles, hardware, machinery, electrical appliances, packaging, kitchenware, lighting, logo fonts, advertising, fitness equipment, handicrafts, glasses and other industries. All machines have passed EU CE certification, US FDA certification and ISO 9001 certification. It has a broad customer base in more than 150 countries and regions including the United States, Canada, Australia, Europe, Southeast Asia, and Africa.

Buy sheet metal laser cutting machine, MYST laser is your satisfactory choice.