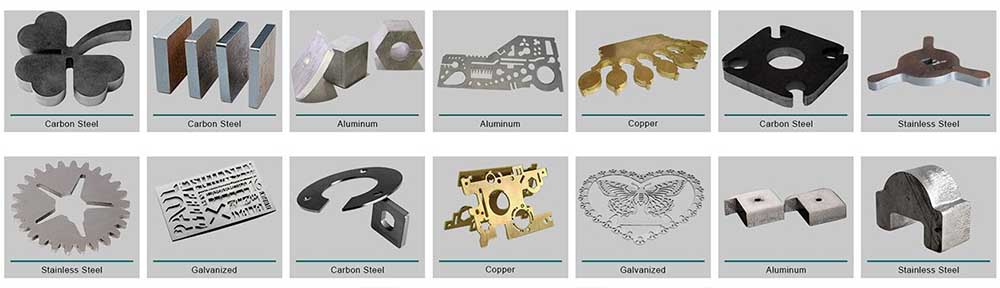

Fiber laser cutters are playing an increasingly important role in industrial manufacturing and other fields, and have become the "main force" to promote the development of the industry. More and more companies are purchasing metal laser cutters for production. A staff member must be clear and memorable to ensure his personal safety, and be responsible for himself, his work, and the company. Today, MYST Laser will share with you the safety knowledge that workers need to keep in mind when operating them.

1. Formulate and follow equipment operating regulations

Before using the fiber laser metal cutting machine, the operating procedures of the equipment should be formulated and strictly followed. Check the safety facilities of the system before starting up, especially the switch of the shutter. Maintain the machine in time to ensure the safety required by wrongdoing before, during, and after use.

2. Fire extinguishing equipment must be equipped on-site

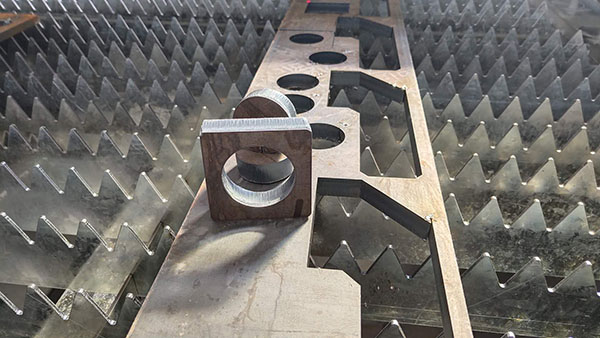

The working principle of the fiber sheet metal laser cutter is to focus the laser light emitted from the laser into a high-power density laser beam through the optical path system. The laser beam irradiates the surface of the workpiece to make the workpiece reach the melting point or boiling point, while the high-pressure gas coaxial with the beam blows away the molten or vaporized metal. As the relative position of the beam and the workpiece moves, the material will finally form a slit, so as to achieve the purpose of cutting. During this cutting process, sparks and heat will be emitted. Therefore, the storage of flammable materials near the machine may cause a fire hazard. The working area of the machine should be equipped with fire extinguishers and other fire fighting measures. Operators should be familiar with fire fighting knowledge and know-how to use fire fighting appliances.

3. Manage the location of the laser cutting machine as a dangerous zone

The area where the fiber laser cutting service metals located should be designated as a hazardous area, and the area should be enclosed with a telescopic isolation belt, and the laser leakage outside the hazardous area should be guaranteed to be below the Class I reachable emission limit. Warning signs should be set up at the entrances and exits of the danger zone so that people will understand that this is a danger zone. The laser cutting machine has laser radiation when it is working, and no one is allowed to enter.

4. It is strictly prohibited to operate after fatigue and drinking

The use of laser processing equipment such as metal laser cutting machines is at a greater risk. If you are negligent, it is very likely to cause injury. Therefore, it is strictly prohibited to operate the best metal laser cutting machine after fatigue and drinking.

5. Protect your eyes

When working with a laser cutting fiber machine, the staff will habitually stare at the metal being cut. This subconscious action is actually very harmful to the eyes. You must wear goggles for protection. Function, because the cutting head will produce a lot of sparks during the process of cutting metal. The high brightness of the sparks will bring a tingling sensation to the eyes, cause certain damage to the cornea and retina, and cause vision loss and inability to see things. The situation occurs, so it is necessary to wear goggles.

6. Protect the respiratory system

A large amount of dust will be generated during the cutting of metal by the fiber laser cutting machine working principle. This dust will enter the lungs through the trachea and respiratory tract through breathing and will cause certain damage to the entire respiratory system. Therefore, dust-proof equipment should be used during the operation of the machine. Masks are very necessary and also a manifestation of being responsible for physical health.

7. Protect the skin

The fiber cutting laser machine will generate high heat during the working process, accompanied by the splash of sparks, which will cause certain damage to the exposed skin of the operator in the working environment. If you stay in this environment for a long time, you will not be exposed to your skin. To protect the skin, long-term exposure to laser radiation and high-temperature roasting will cause serious adverse effects on the skin tissue, reduce the skin’s self-repair ability, and then reduce its own immunity. Therefore, the staff must wear protective clothing during the operation. , Wear gloves on your hands and be responsible for your own health.

In order to have a better life and better work, the staff must ensure their personal safety and health every time the machine operates the optical fiber cutting machine. The safety precautions must not be sloppy. Mister Laser is sincere I hope every staff member is safe and healthy, works happily, and lives with heart.