Under the background of the rapid development of the manufacturing industry, cnc fiber laser cutting machines came into being. As powerful high-tech products, they are widely used in various industries. The birth of laser metal cutting machines has laid the foundation for the rapid development of industry. People's need for work efficiency, the exchange table custom metal laser cutting has become a hot target in the cutting machine market. It is sought after by people for its high utilization rate of machine tools and no standby time for loading and unloading.

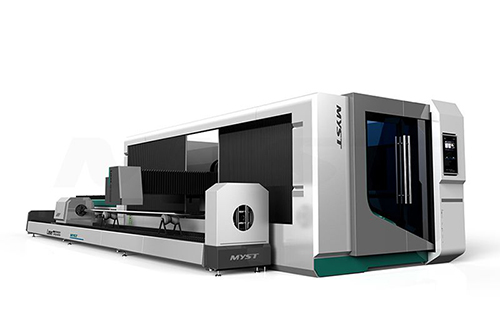

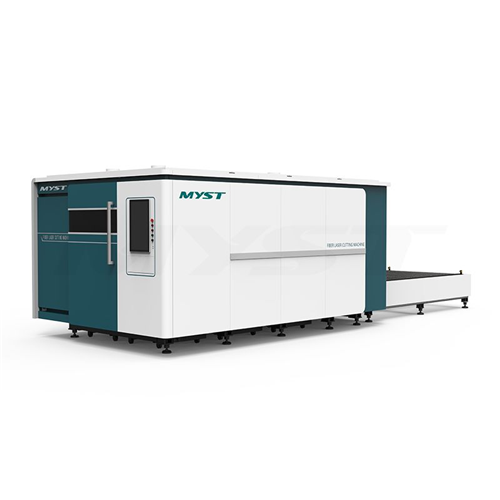

Laser cutting machine for metal sheet is a cutting machine that uses a fiber generator as the main tool to realize automatic cutting through a numerical control system. There are two types of best fiber laser cutting machines, one is a single working platform laser cutting machine, and the other is a switching table laser Cutting machine, the difference between the two is that the single worktable laser cutting machine has only one worktable that can be used for work, and the exchange table laser cutting machine has two worktables, and the two platforms can exchange positions when working.

In the field of sheet metal processing, the exchange table fiber laser metal cutting is widely used. Because of its fast cutting speed, good cutting effect and high work efficiency, it has replaced other processing tools and has become a new favorite in the field of sheet metal processing.

The appearance of the exchange table diy fiber laser cutter has greatly improved the utilization efficiency of the laser cutting machine, and realized the cutting and completing the loading and unloading work at the same time. At present, the exchange table on the market mainly adopts the hydraulic lifting type exchange table, which is simple to install, and usually uses a synchronous motor oil pump to solve related problems. The exchange table metal fiber laser cutting machine has ultra-low cost and low power consumption, and can use air to cut various metal sheets. The cutting speed is fast, the interchangeable worktable has high loading and unloading efficiency and labor saving, high automation level, simple operation, no pollution, high cutting precision, good cutting quality, and low maintenance costs.

The rapid development of the manufacturing industry has driven the development of the domestic manufacturing industry. In order to catch up with the international trend and continue to promote the progress of domestic processing technology, the gap between the production level of desktop fiber laser cutting machines and developed countries is getting smaller and smaller. More and more people who have the need to purchase machines have turned their attention to China. The hobby laser cutter metal of exchange table produced by MYST has been favored by many domestic and foreign customers in the market.